Provoost.engineering’s portfolio includes quite a few unique and groundbreaking industrial construction projects. A very nice example is the new MSC PSA European Terminal (MPET) at the Deurganck dock in the port of Antwerp.

This terminal includes a maintenance and repair shop for straddle carriers. A straddle carrier is a freight-carrying vehicle that carries its load underneath by straddling it. Cradle carriers stack and move containers that have been unloaded from a ship moored at the quay of the dock, and then store them in the terminal or transfer them onto a truck. As the terminal at the Deurganck dock was in full expansion, the existing terminal infrastructure was no longer sufficient to provide for regular maintenance and repair of the 200 straddle carriers used daily.

The maintenance and repair shop, designed by Architectenassociatie Angst & D'hoore, consists of 2 massive volumes connected via a smaller central space. Within both volumes, sufficient space is available to service 12 straddle carriers simultaneously.

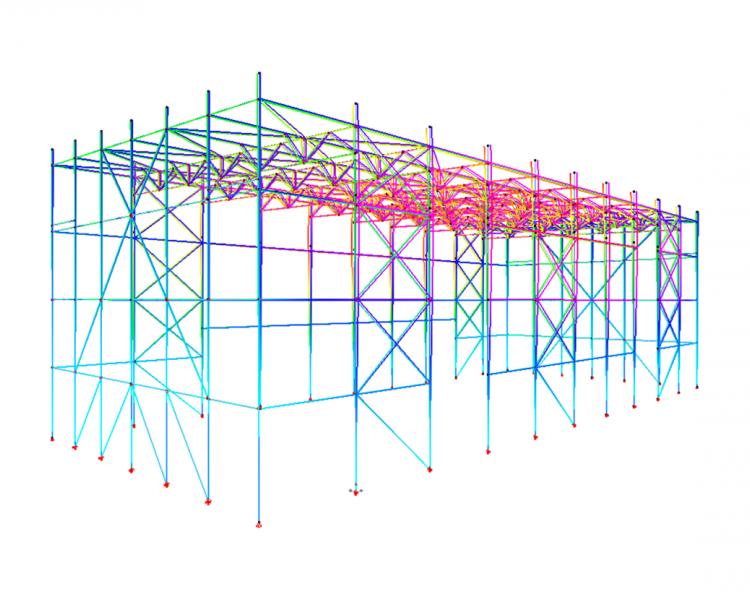

View of the steel structure and the walkways within the MPET maintenance and repair shop at the Deurganck dock in the port of Antwerp

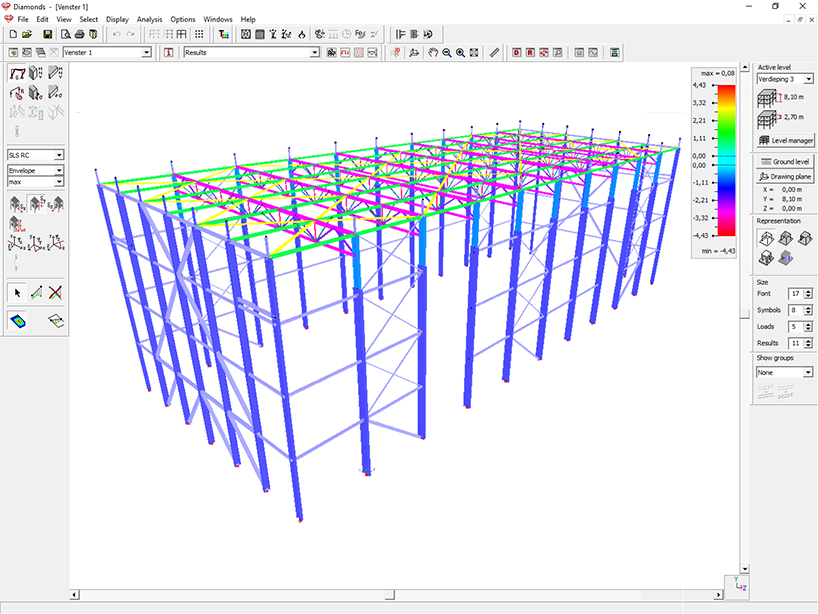

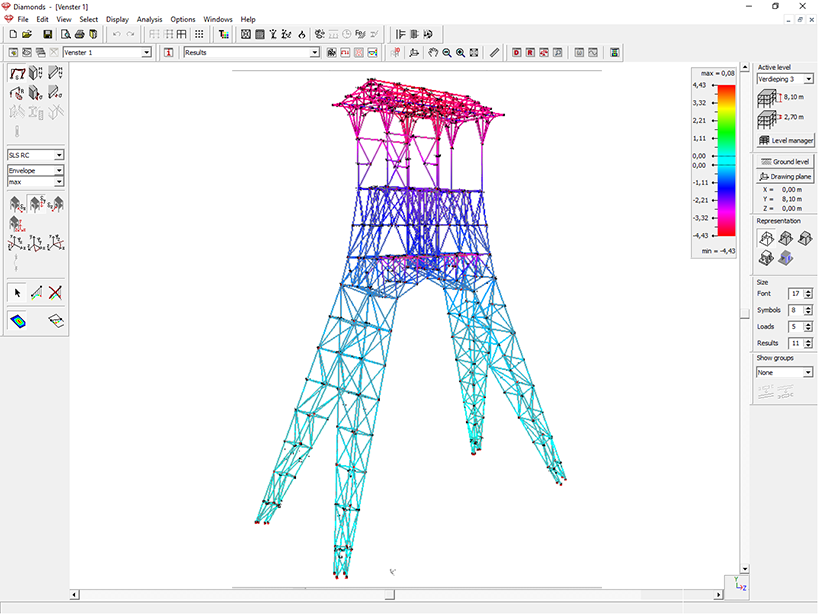

3D Diamonds structural analysis model for the MPET maintenance and repair shop for straddle carriers

This kind of project poses quite a few exciting challenges from a structural analysis point of view. The mere size of the buildings is sufficient to warrant that. Each building is 25 meters high. The gates through which the straddle carriers enter have a height of 18 meters. In addition, all straddle carriers must remain readily accessible during maintenance or repair container lifts at different levels.

The result is an impressive steel structure on which walkways are mounted at various heights. Although we could have integrated all of this into a single 3D Diamonds analysis model, we preferred a phased approach tuned to the specific challenges that come with each aspect of the design. That is why we opted for a 3D structural analysis model of the load-bearing steel structure, in combination with a series of analysis models of the various walkways in the maintenance and repair shop.

We had to pay particular attention to the horizontal loads induced by the straddle carriers whenever they moor at the maintenance walkways. Because some kind of collision cannot be entirely avoided during mooring, it is vital to account for the associated horizontal loads during the structural design analysis. Besides, a buffer element must be incorporated in the design of the walkways to absorb and transfer these mooring loads elegantly.

The foundation of the maintenance and repair shops posed a couple of additional challenges. The main reason was that each building stands on an 8-meter high sand layer deposited on top of the existing polder land. Due to the weight of that sand layer, significant settlements of the polder subsurface can be observed. To avoid differential settlements, it was necessary to design a pile foundation carrying the shop’s load-bearing steel structure as well as the shop floor.